We are an ISV with a strong focus on scheduling and Microsoft Dynamics 365 Business Central. Our software is "made in Germany", and we are fast and flexible. We work with 500+ partners on all 5 continents.

Product used: VAPS

Before using the VAPS, the company’s planning was done by extensive Excel sheets, but, according to Gary Browning, Business Unit Manager at the GATIC site in Dover, they were always “quite keen to have a visual planning tool to drag and drop things.”

Since working with advanced production scheduling software, Alumasc WMS has achieved significant improvements: streamlined order management, better integration with Dynamics 365 Business Central, error detection, and easy and efficient changes to the plan.

Product used: VPS

The German company planned its production "analog" for a long time. The resulting problems were to be solved by using an ERP without a planning board, but this did not lead to a satisfactory result. Only the VPS brought more efficient planning, smoother processes, and more satisfied employees. At Winter + Freis, they are delighted that "we have a very good tool with which to work".

Product used: VAPS

After having introduced Microsoft Dynamics as ERP in the company and having worked with it for some time, it became clear relatively quickly that an additional scheduling tool was needed to better manage the production processes. In particular, estimating and keeping delivery dates was improved significantly. "We are coming from almost no on-time deliveries to 80% to 90% deliveries on time”. The sales department was also happy because for the first time they “could inform our customers about the expected delivery”.

Product: VPS

Before using Microsoft Dynamics 365 Business Central together with the Visual Production Scheduler (VPS), the company planned their production using Excel spreadsheets and a weekly meeting at the management level lasting around three hours. The implementation of the production scheduling software led to significant improvements at Stummer after just a short time: Complete omission of the weekly planning meeting, freeing up around 80 management hours per month for more productive activities, reliable delivery date forecasts, overview for production employees of their current and future orders.

We launched our first production scheduling add-in for Dynamics NAV back in 2013. Since then, we have been continuously learning more about NAV and Business Central manufacturing. While learning and working with hundreds of customers and partners around the globe, we have consistently enhanced and empowered our production scheduling software.

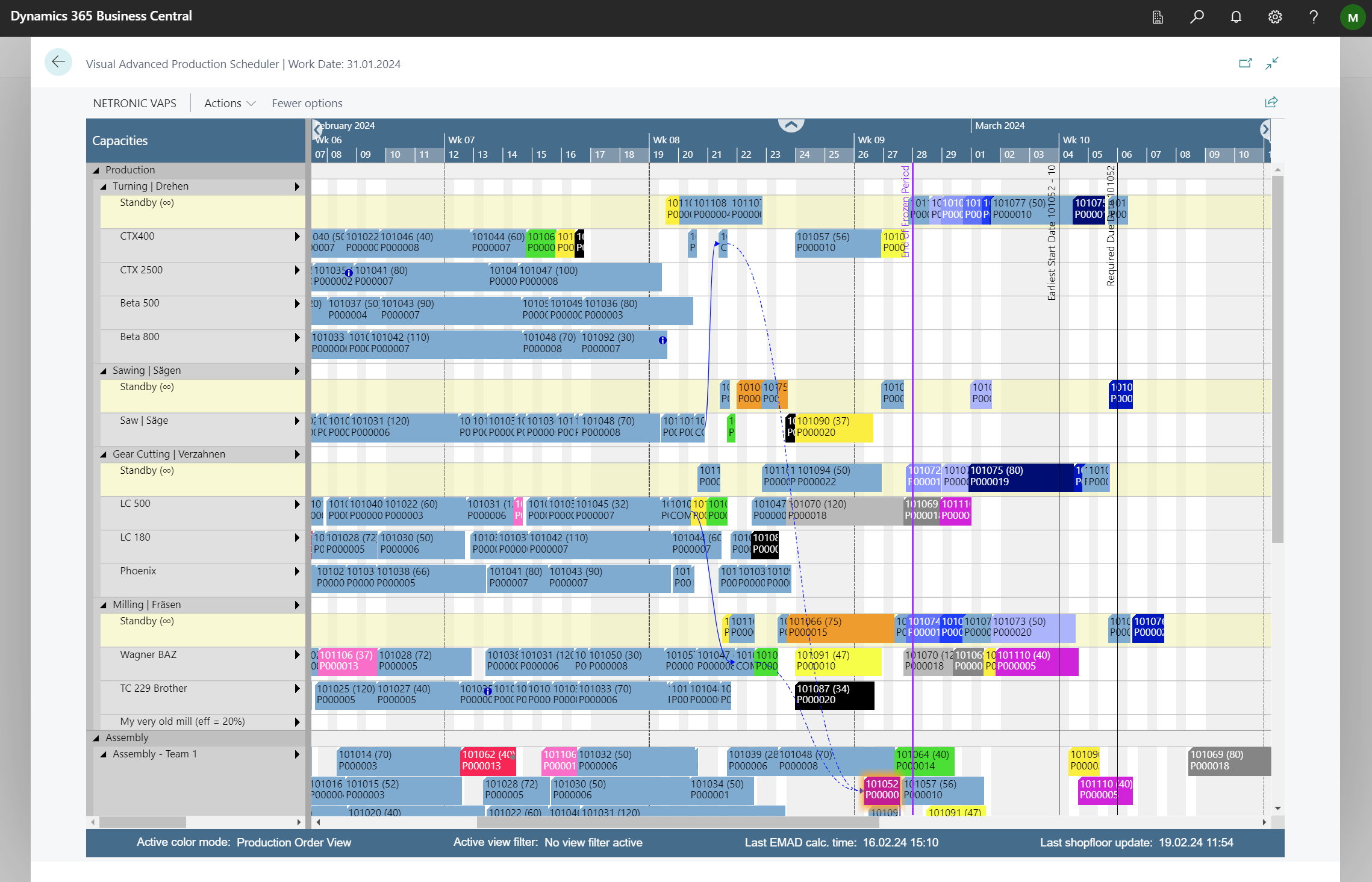

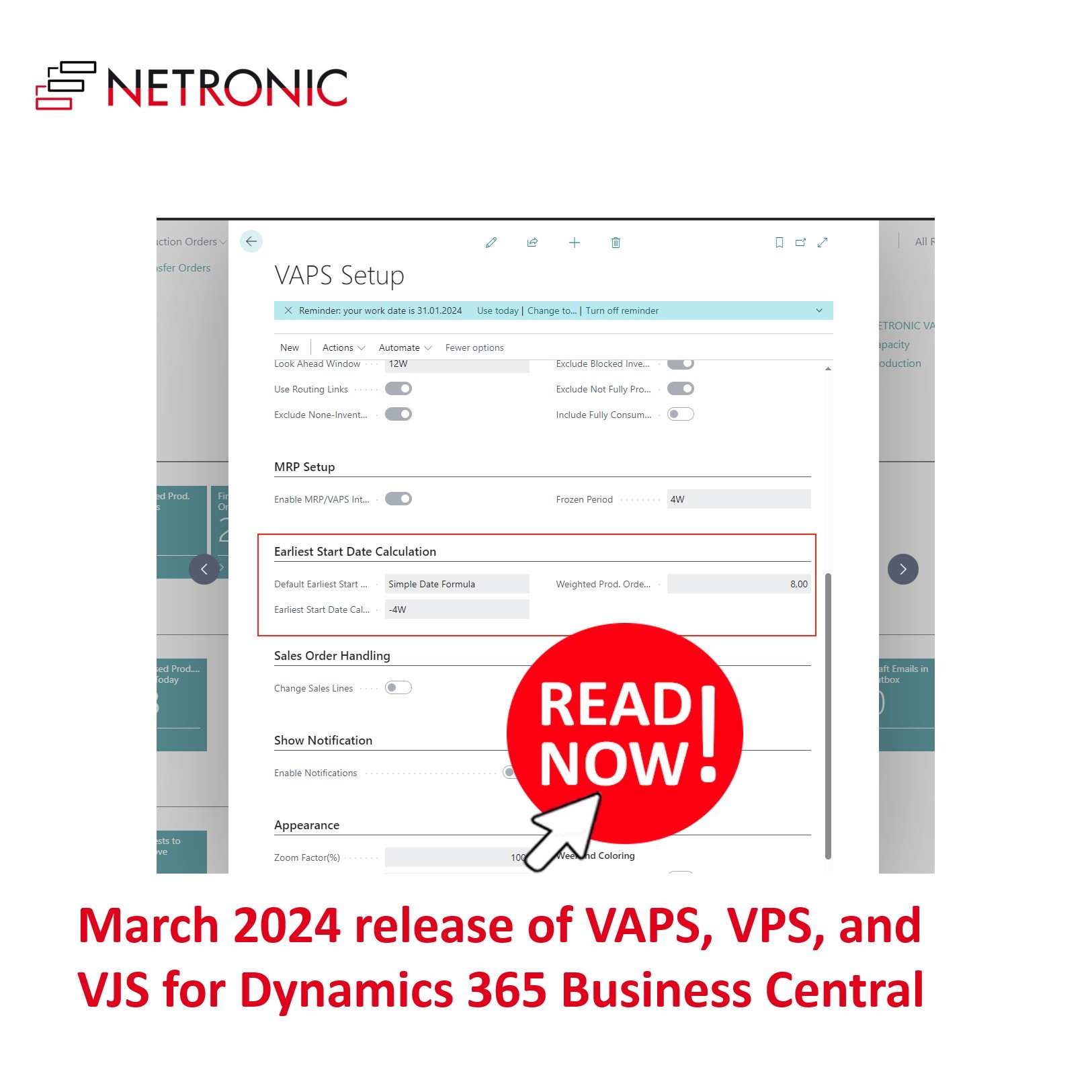

Our flagship product is the VAPS - the Visual Advanced Production Scheduler for Business Central. It provides visual yet advanced scheduling for SMB manufacturers. The VAPS takes both into account: finite capacity and material availability. It is fully integrated into Business Central and leverages more than a decade of gaining Business Central manufacturing expertise.

Here, you'll learn how production scheduling helps you and your customers to get more out of Microsoft Dynamics 365 Business Central. Whether you're looking to improve your OTD, better manage production orders that are reserved for concrete sales orders, or increase efficiency, we've got you covered. All videos are hands-on and provide concrete "how-to" guidance.

Learn more about Business Central manufacturing and our products from our production scheduling authors.

We know that finding the right scheduling software is sometimes hard. We also know that sometimes it is hard for clients to figure out which of our scheduling software products is best for them.

If you are unsure how to proceed, or if you would like to learn a bit more about our offerings, book a 15-minute explorative session with us.

We will keep this meeting to 15 minutes. We will do no demo, and we will not pitch software. In essence, we will ask a bunch of questions to understand your scheduling challenge.

Based on this, we either honestly tell you that our products are not a good fit for you. Or - we jointly come to the conclusion that we might be an option for you. In that case, we use these 15 minutes to agree upon the next steps.