With the Visual Advanced Production Scheduler (VAPS) for Dynamics 365 Business Central, customers have seen:

1) On-time deliveries of up to 90%

2) Reduced transportation costs due to better scheduling

3) Increased customer + employee satisfaction

The VAPS fundamentally changed the way we manage and run our production. On the one hand, it gives us transparency and the right tools to achieve stable and seamless production processes. On the other hand, it allows us to react to unplanned incidents quickly and to make the right decisions fast.

Ignacio Garrido Ceca | Managing Director Adix

1.

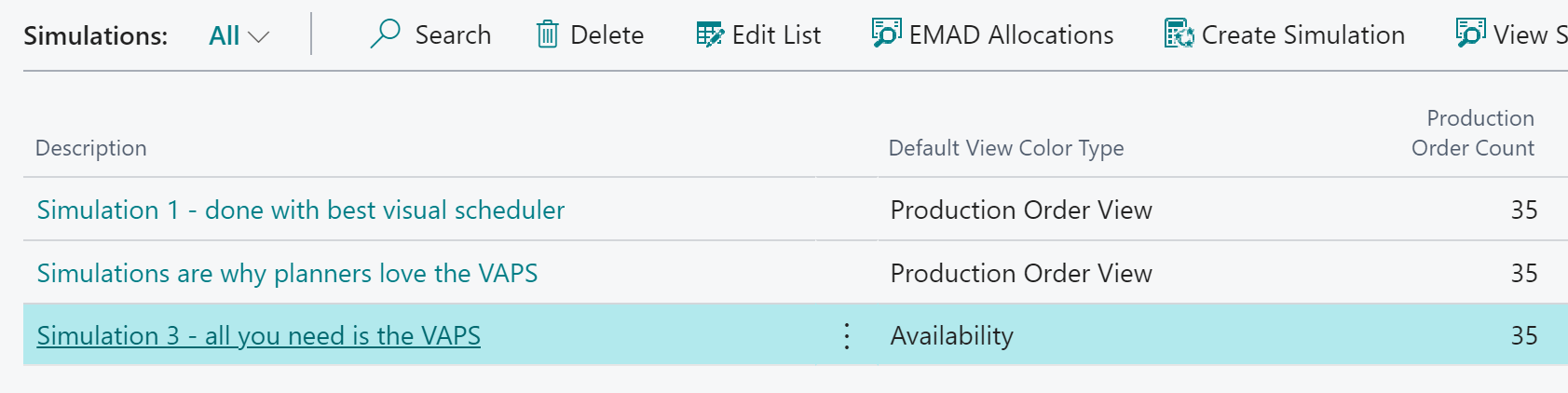

In the VAPS, you can run a simulation of your production schedule. Make both drag & drop and automatic changes to your schedule - and immediately see the impact on all downstream processes.

Run another simulation, and make different changes.

Understand dependencies, spot late orders, and see the material availability status at one glance.

Compare the simulations by KPIs such as the number of late orders.

Make decisions fast – based on what you see and understand.

2.

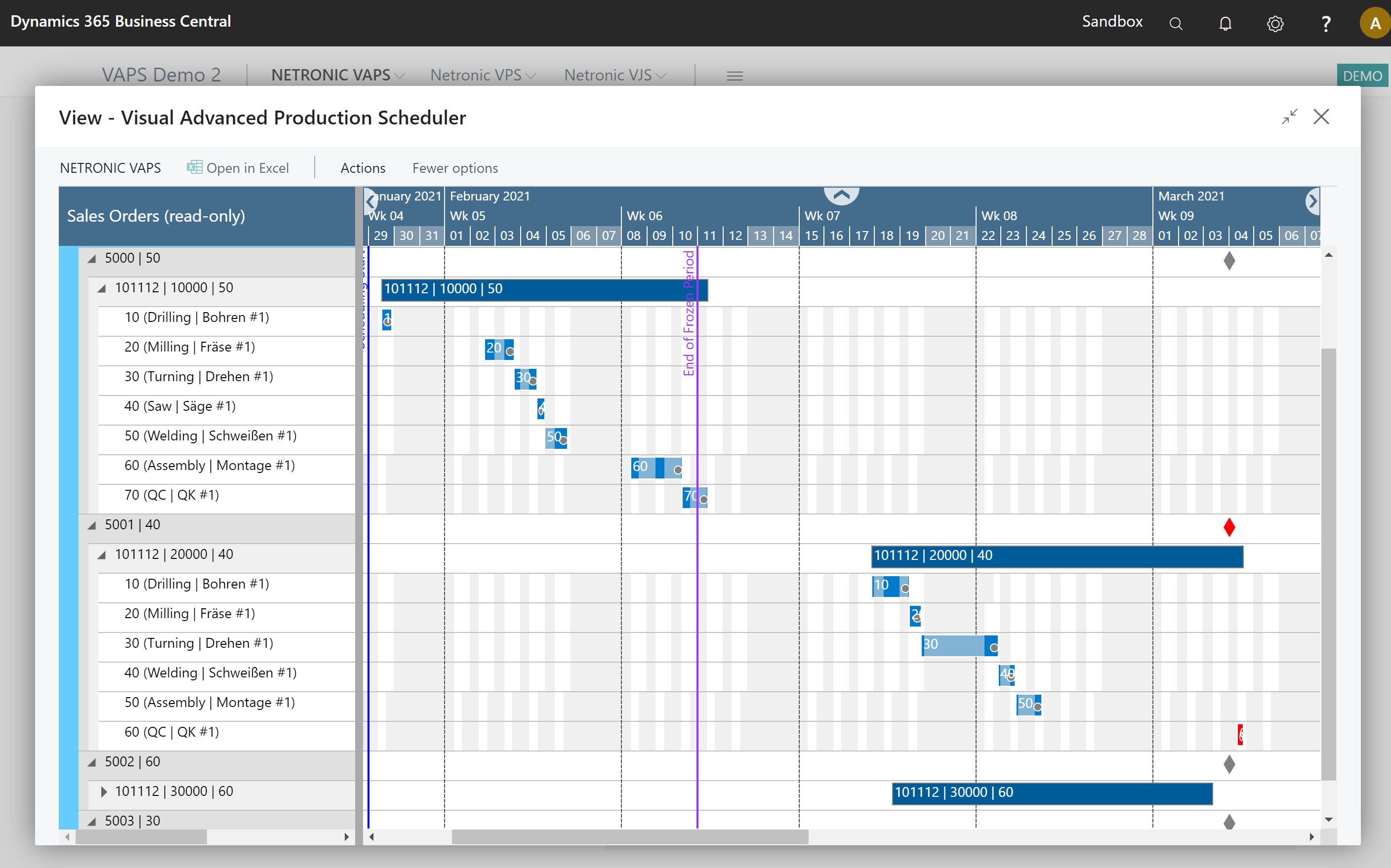

Manage your schedule.

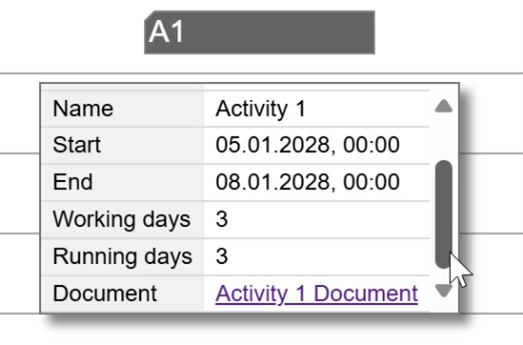

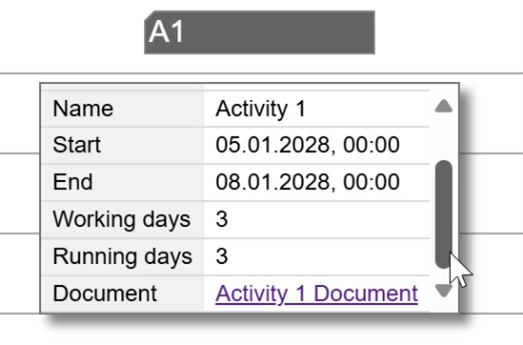

Understand the workload & timelines. See when the items from your sales order are scheduled, and on which machines.

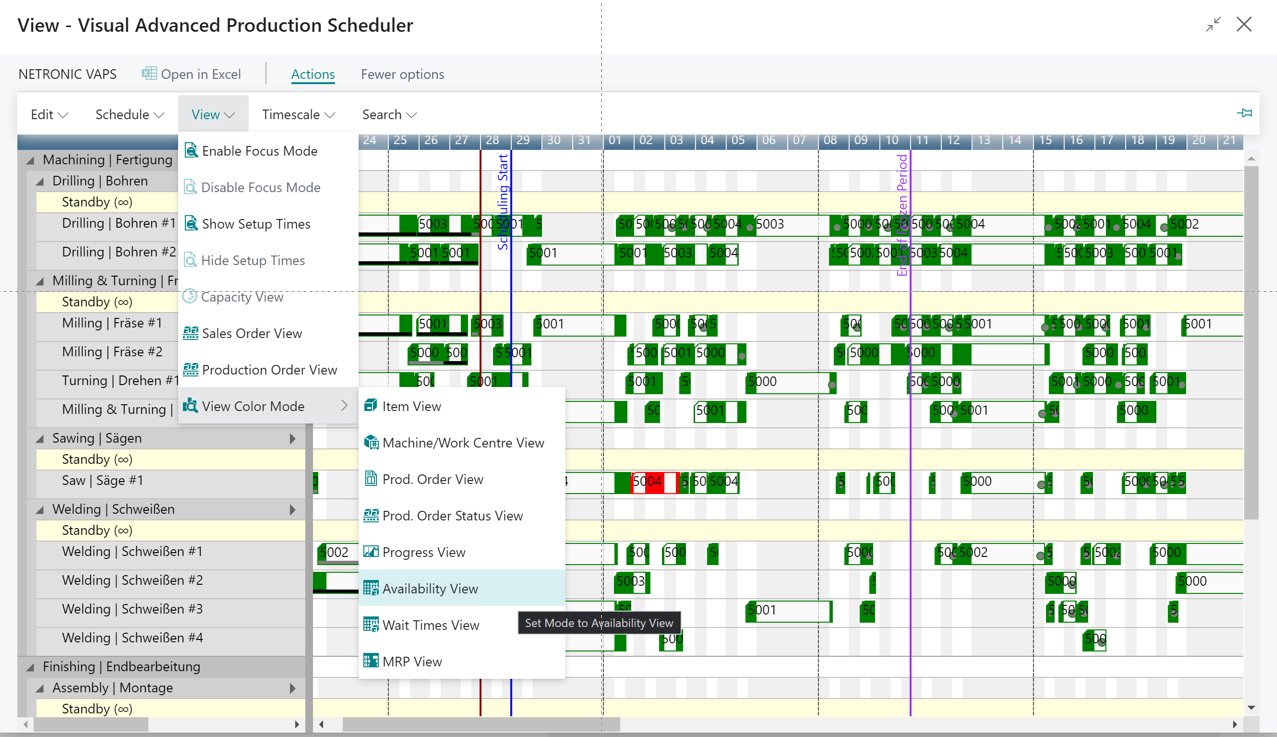

Look at the Sales Order View in the VAPS, and immediately understand which items will be finished when - and which items will be finished too late.

Take this information to

give reliable delivery time commitments (as each finish date information is based on a realistic, finite capacity schedule)

make corrective scheduling actions for all late orders

3.

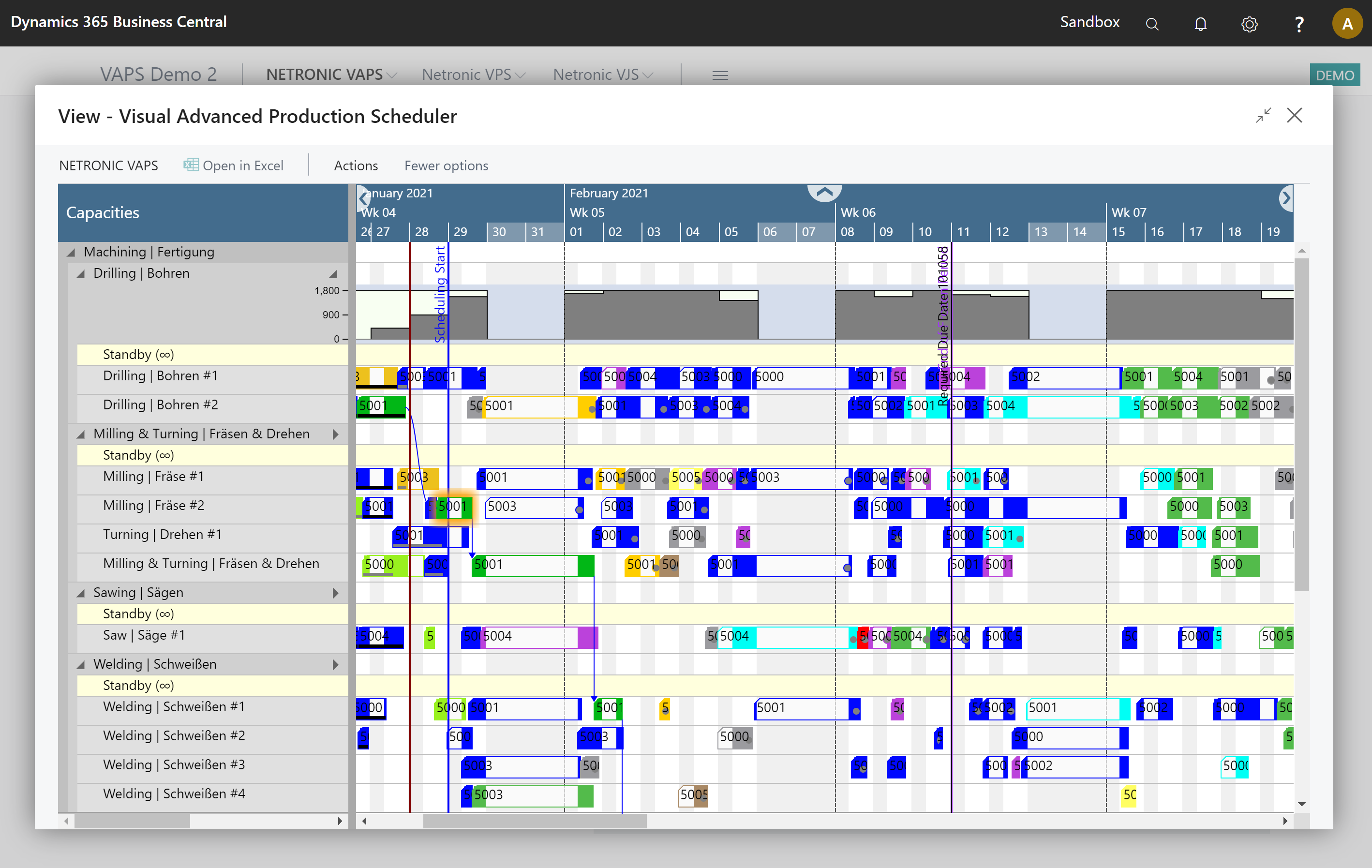

See the resource load at one glance.

Understand capacity & bottlenecks thanks to intelligent color schemes.

Apply the "fill idle times" function and minimize idle times on your machines. The result: more efficient operations and increased throughput thanks to better resource usage.

With the VAPS, you will produce more - without the need to invest in new machines.

"The VAPS made planning significantly easier compared to our previous use of spreadsheets. The visual nature of the tool allowed for quicker and more intuitive adjustments, eliminating the need for extensive copying, and pasting. With the VAPS, we can confirm delivery times to our customers with much more precision than before.”

Gary Browning | Business Unit Manager Alumasc

We offer two different visual production scheduling apps for Microsoft Dynamics 365 Business Central: the Visual Production Scheduler (VPS) and the Visual Advanced Production Scheduler (VAPS).

This 60-minute in-depth video shows what both apps have in common and also how and why they differ. The video starts with planning production orders by Business Central only - without any visual scheduling extension. Then we add the power of a visual drag & drop scheduler (VPS) to it before we add more scheduling power such as finite capacity scheduling (VAPS).

The VAPS does not just support one version of the schedule. You can create multiple simulations and scenarios, compare them with meaningful KPIs, and then publish the one that fulfills your purpose best.

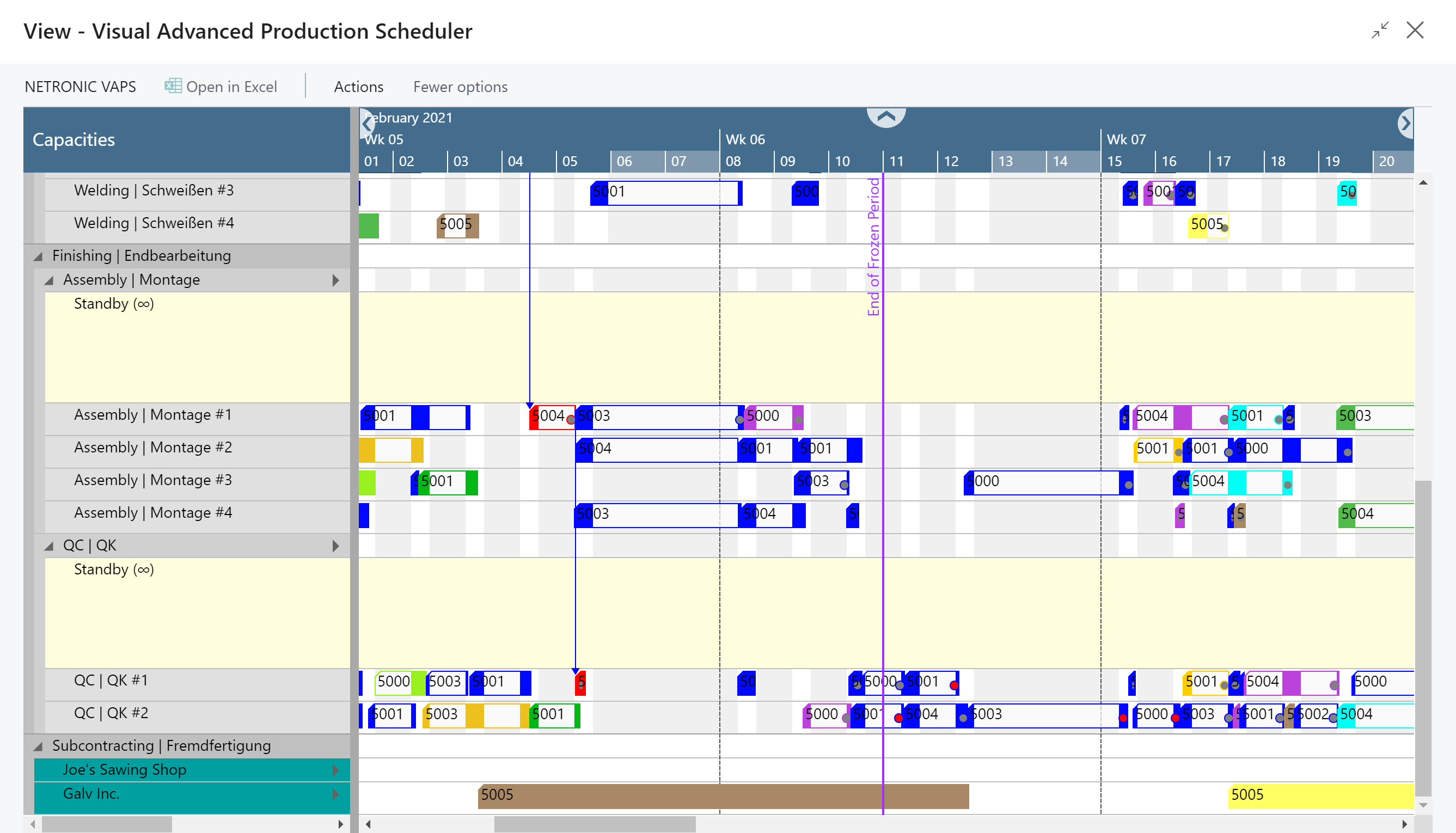

Whenever you create new production orders (from the planning worksheet, via sales orders, or manually) you see them on the standby resource.

You can add them all to the schedule automatically - taking into account the current capacity utilization.

The automatic finite capacity scheduler provides you with realistic delivery times instantaneously.

You can also apply drag & drop scheduling with the VAPS. This is the scheduling tool of choice to deal with exceptions. E.g. if you have to squeeze in a rush order.

As the VAPS is a finite capacity scheduler, there is no overbooking of resources.

As a consequence, you can immediately see all downstream impacts of any scheduling change you make.

With the VAPS, we calculate the EMAD. EMAD stands for earliest material availability date. We provide EMAD information on the production order line level.

The color scheme "availability view" lets you see all those production orders scheduled to start before the EMAD (in red).

The EMAD is also shown when you drag & drop production orders, and you can configure the VAPS so that the EMAD does not get violated.

Define allowed alternative machines per routing step. Also specific factors for the runtime and the set-up time (e.g. if machine 2 is slower than machine 1).

See all allowed machines (highlighted; all machines: greyed out) when making drag & drop changes.

The factors automatically get applied by the finite capacity scheduler.

Our finite capacity scheduler extension meets the highest Microsoft quality standards because it is approved for and available on Microsoft AppSource. We provide an updated version of the VAPS every quarter and submit each updated version for a new AppSource validation.

Of course, you can download the Visual Advanced Production Scheduler from the Microsoft AppSource. With the download, you have the right to trial for 30 days.

However, we recommend that you do not just test it on your own.

Although visual, the Visual Advanced Production Scheduler has a lot of powerful (hidden) features. We want to make sure that you manage to unleash the full value of visual production scheduling, and hence we designed the Guided Trial to get you going both fast and purposeful.

Book a meeting with a scheduling expert to discuss how you can get going now.