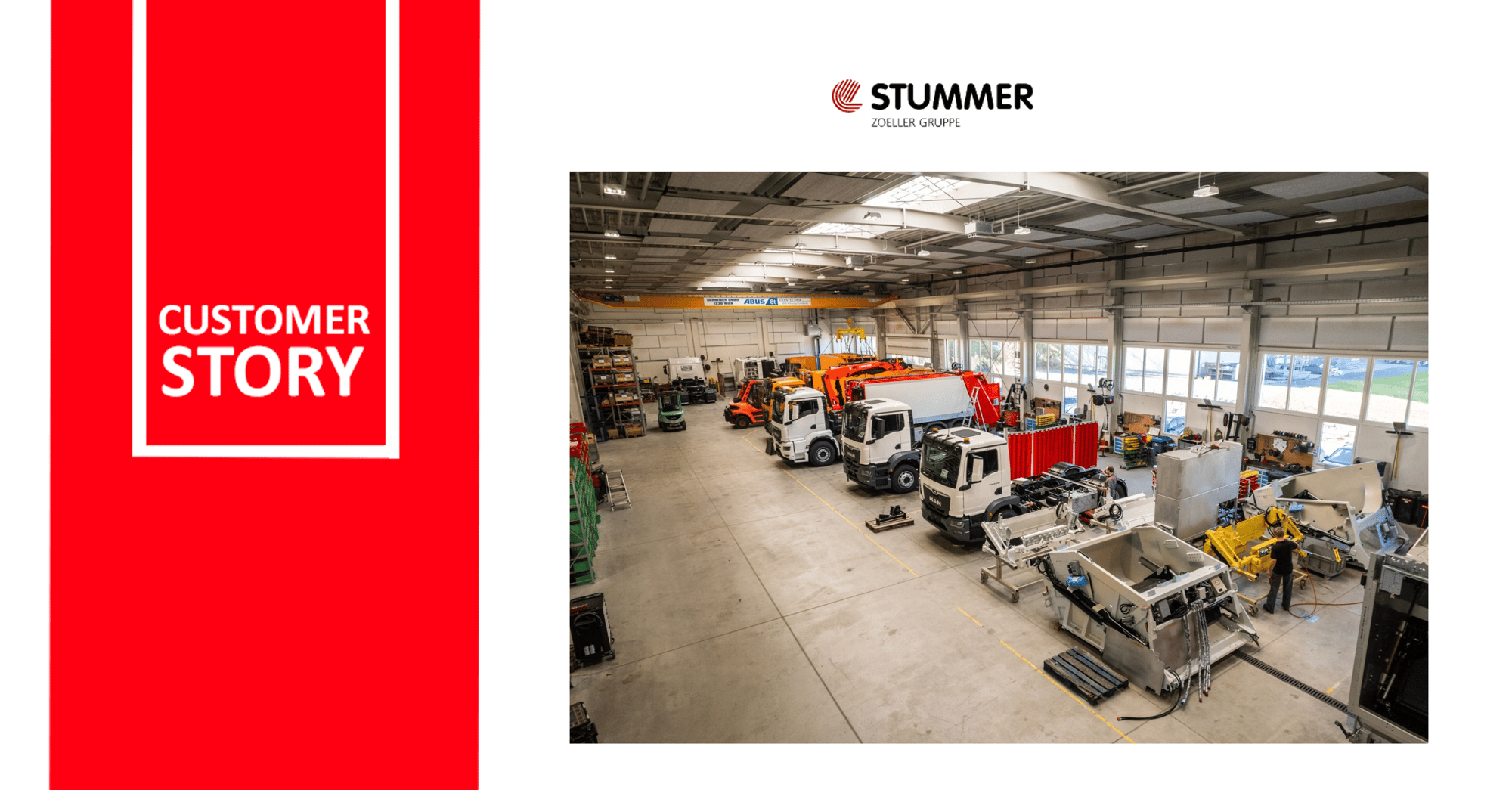

Thanks to the VPS, the Austrian producer of refuse collection vehicles saves 80 hours planning effort and gains transparent planning and reliable delivery time commitments.

Thanks to the VAPS, Alumasc Water Management Solutions (AWMS) from the UK streamlined their order management and can now make realistic delivery time commitments and keep the schedule current.

The Belgian provider of blending and packing of car cosmetics and industrial cleaning products gains transparency and flexibility thus making their planning a lot easier.

The Italian contract manufacturer PMP wins precise estimation and keeping of delivery dates and thus increases customer and staff satisfaction by using the VPS.

The VJS ensures transparent processes and more efficient planning at the German full-range supplier of drying and heat treatment plants.

.jpg?width=3240&name=Unipromet-61%20(1).jpg)

By using the VPS, the Serbian company Unipromet streamlined their complete production planning process and gained a stable basis for decision making.

By using the VAPS, the Spanish producer of explosion protection systems made their production processes more precise and transparent, thus being able to keep delivery date promises, gain significant savings in transportation costs, and improve their employees' happiness.

With its outstanding EAM software, the Danish ISV focuses on companies with high-value assets. The Scheduling Board add-on provides comprehensive scheduling information in one view, allows manual allocation of work orders as well as has a direct connection to D365 BC.

PrintVis is the Microsoft certified Print MIS. The PV Planning board offers powerful features to help planners to adjust the job schedule quickly and save.

For their state-of-the-art service management software, Dysel was looking for a development tool for interactive Gantt charts with advanced visual functionality that fully integrates into Microsoft Dynamics 365 BC and with the VSADT they found the perfect product.

The Italian company used to plan masses of projects with Microsoft's ERP system Dynamics NAV but at some point this was not sufficient any more. Only the use of the VJS brought transparent data structure, better informed employees and more efficient planning.

The German company planned its production "analog" for a long time. The resulting problems were to be solved by using an ERP without a planning board, but this did not lead to a satisfactory result. Only the VPS brought more efficient planning, smoother processes and more satisfied employees. At Winter + Freis, they are delighted that "we have a very good tool with which to work".

Concentrating all important employee data in one place and then importing it into the planning board via individual settings - this idea gave rise to a new visualization tool that helps temporary employment agencies to plan and track their employee assignments easily and intuitively.

For a long time, the Danish company used Excel for their planning. In addition, the employees verbally kept each other informed about orders pending and those waiting to be processed. The VPS improved one criteria quickly: "Our KPI for delivery on time to customers has increased dramatically" . But this is not the only added value gained by the VPS.

Support for daily sequence planning - this is what the customers of Add*ONE Simultaneous Planning of Inform wanted. Therefore, Inform developed a detailed planning component in combination with an interactive planning board with a lot of business logic, which enables the planner to make faster and more reliable decisions in his daily work routine.

When lead times shifted, the timely and accurate dissemination of information was a big challenge for Davis & Shirtliff, a Kenya based company for innovative solutions for water and energy systems. They used Microsoft Excel or Microsoft Project for production planning. Now they use the Visual Production Scheduler, that provides the transparency needed to keep delivery on time.

The Swiss manufacturer of food supplements wanted to reduce the intermediate cleaning of the machines to a minimum. At the same time they need to react flexible to new orders and short delivery dates. This worked out: with the help of an individual extension of the Visual Production Scheduler.

Beas (today Boyum) develops a visual APS Solution with resource planning for SAP Business ONE. By this, the planner not only gets a transparent overview of the very complex data structure characterized by many dependencies, but also can intervene manually in the planning process.

Today, Dickies uses the „Visual Embroidering Scheduler“, thus not only gaining much more overview for their planning but also a considerably better machine utilization without getting into trouble with their delivery dates.

After upgrading from NAVISION to Microsoft Dynamics NAV 2015, Service4CtS uses the Visual Service Scheduler to schedule their service technicians.

ESK Schultze used the graphical planning board in the classic client of NAV. When upgrading to NAV 2013, they missed their visualization of manufacturing data. Today the VPS fully replaces the old planning board.

Building cruise liners require complex planning. The extending ship size, higher demands and cost pressure even makes it more challanging. A visual planning board lets planners schedule the great number of single processes faster.