Stummer Kommunalfahrzeuge Ges.m.b.H. from Austria has been producing refuse collection vehicles for the municipal, state, and private waste disposal industry at its plant in Bischofshofen for 40 years. Stummer is a subsidiary of the Zöller Group, the leading supplier of these systems in Europe. Production is carried out on an individual order basis.

Before using Microsoft Dynamics 365 Business Central together with the Visual Production Scheduler (VPS), the company planned their production using Excel spreadsheets and a weekly meeting at management level lasting around three hours.

On the recommendation of their Microsoft Dynamics partner, NAVAX, Stummer decided to use the ERP system Dynamics 365 Business Central and the VPS as a supplement for graphical production scheduling. The planning board quickly won them over with its powerful functions and options.

The implementation of the production scheduling software led to significant improvements at Stummer after just a short time:

Complete omission of the weekly planning meeting, freeing up around 80 management hours per month for more productive activities

Seamless integration with Dynamics 365 Business Central

Reliable delivery date forecasts

Overview for production employees of their current and future orders

Before switching to Business Central, planning in the company was carried out using Excel spreadsheets and, according to Andreas Schweiger, BSc, Production Manager at Stummer,

Before switching to Business Central, planning in the company was carried out using Excel spreadsheets and, according to Andreas Schweiger, BSc, Production Manager at Stummer,

"therefore often only 'pi times thumbs' and delivery date commitments were difficult because capacities could only be estimated."

In addition, a management meeting lasting

around three hours was held every Friday to plan for the coming week. As Florian Mutinelli, responsible engineer for order management at Stummer, reports, "These meetings were often heated and there were often arguments."

Stummer specializes in the make-to-order manufacturing of municipal vehicles, including refuse collection vehicles, roll-off tippers, skip loaders, glass collectors, and washing vehicles. The specific components are ordered from various manufacturers according to Stummer's specifications. Painting, assembly, and finishing are done at the plant in Bischofshofen before the vehicles are subjected to thorough quality and functional testing.

The core of Stummer's operations revolves around make-to-order manufacturing, where the primary elements - body, chassis, and lifter - are pre-fabricated by the parent company. The subsequent steps, including assembly, configuration, and software integration, are manually carried out in-house.

In make-to-order manufacturing, precise production planning is crucial to ensure communication and adherence to delivery times. At the same time, the coronavirus pandemic and material shortages have led to delivery problems with incoming materials in recent years, meaning that planning has become much more dynamic, which requires extremely flexible scheduling.

Excel-based planning could no longer keep pace with the changed situation in terms of material availability and the modern and demanding production processes of an increasingly complex waste management industry: not only was it cumbersome and error-prone, but, as described by Florian Mutinelli, it also harbored a certain amount of potential for conflict. A new type of planning was therefore urgently needed.

The production scheduling software should

be easy to integrate into Microsoft Dynamics 365 Business Central

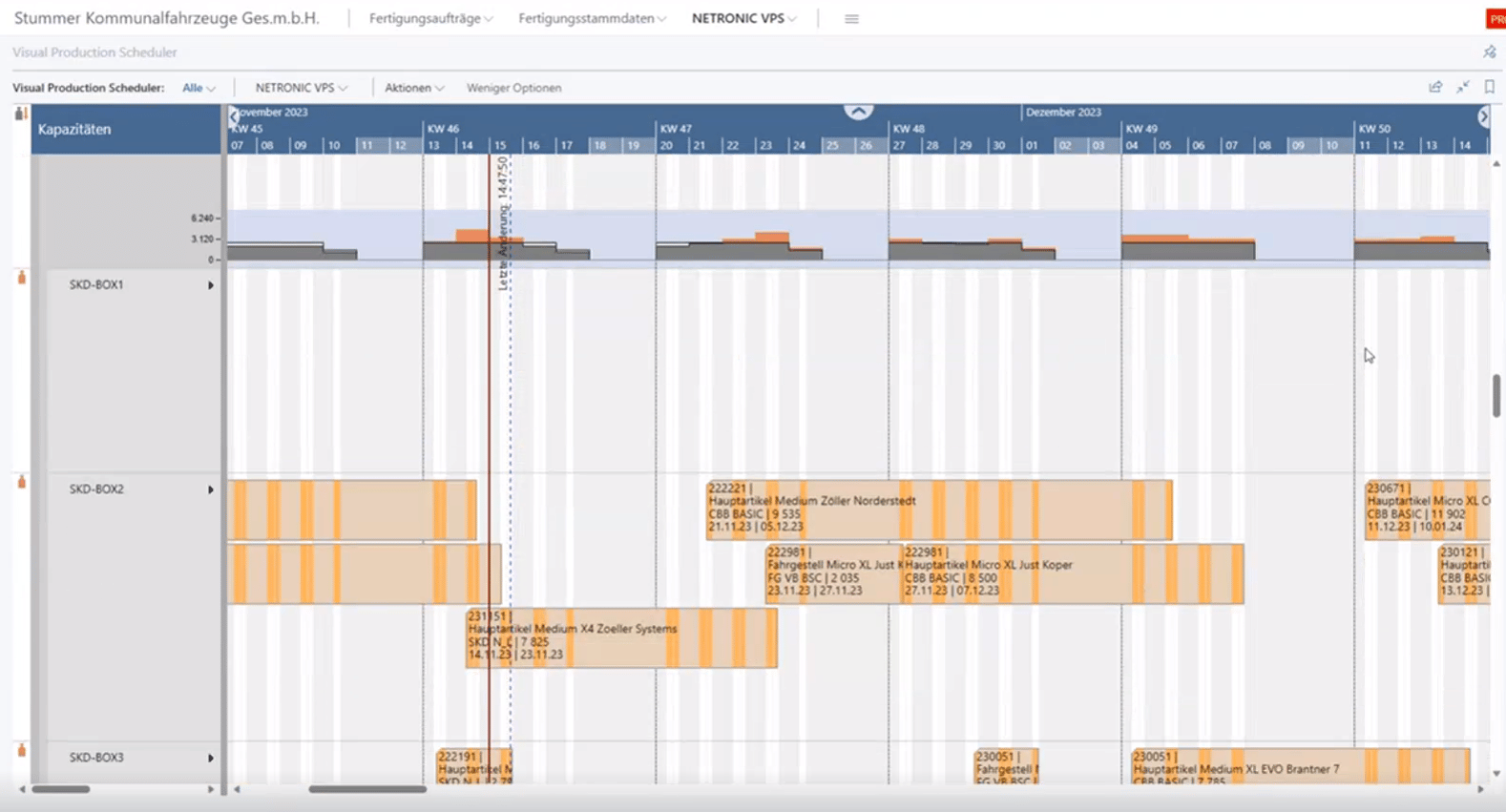

display capacities in a clear view, making it easy to identify capacity peaks and bottlenecks

enable simple and fast plan changes that are written directly back to Business Central

After the parent company's unsuccessful attempt to implement SAP as an ERP system, Stummer was the first company in the group to implement Microsoft Dynamics 365 Business Central on the recommendation of Navax. However, this did not really put their production scheduling process on a new path. Programs that automatically search for capacities were rejected as too complicated. Here too, Navax was able to help and drew attention to the VPS from NETRONIC. "This worked smoothly right from the start and was adopted after a short test phase," says Florian Mutinelli happily.

.

Planning at Stummer now involves an Excel configurator transferring parts lists and routings to Business Central and the production orders being visualized by the VPS and scheduled according to their due date, which is based on the delivery date according to the order confirmation.

The work plans are automatically sent to the respective teams, where they are scheduled for the individual machine centers, i.e. the detailed planning is carried out by the team.

The workshop is now equipped with computers, providing those in charge with a constant overview of upcoming production orders and those to be completed at all times.

The switch to Microsoft Business Central and the simultaneous implementation of the VPS have fundamentally changed the way the company approaches production scheduling. The dynamic capabilities of the VPS enable enhanced flexibility and precision in scheduling, which proves to be crucial in unforeseen circumstances like delivery delays caused by external factors such as the COVID-19 pandemic and material shortages. These can now be identified quickly and you can react accordingly, as Florian Mutinelli explains:

"The VPS provides a dynamic overview that is always up to date. You can immediately see how long the delivery delay is and then quickly and easily move the corresponding work processes using drag & drop. Thanks to the integration with Business Central, the order date is also changed directly in Purchasing. We can always see what is ready and when."

Of course, this also allows more precise delivery date commitments to be made than before. Capacity peaks can also be recognized directly, "which means that certain orders can be brought forward or other measures can be taken to balance out these peaks," says Andreas Schweiger.

Thanks to a transparent and dynamic overview of delivery dates, work schedules, and capacities, the need for weekly planning meetings has been eliminated - probably the most significant improvement brought about by the introduction of the VPS. The considerable management capacity of around 80 hours per month gained in this way can now be used for more productive tasks.

The decision to opt for Business Central and the VPS has not been regretted in Bischofshofen. After just a short time, the VPS in particular brought decisive changes and improvements.

Time and cost savings: The elimination of weekly planning meetings at management level saves valuable time.

Integration with Dynamics 365 Business Central: The VPS makes working with Business Central easier thanks to a graphical and precise live view of the production data. In addition, unlike when using Excel spreadsheets, the data in Business Central is updated directly when changes are made in the planning tool.

Real-time and constantly updated data: The dynamic overview is always up to date and offers a great many evaluation options.

Direct intervention: Capacity peaks, bottlenecks, and errors in the data are easily recognized by the graphical display and allow quick and intuitive reactions

Andreas Schweiger and Florian Mutinelli are highly satisfied with the decision to opt for Business Central and the VPS and praise the excellent cooperation with NAVAX and NETRONIC. They particularly emphasize the quick reactions of the NETRONIC team to inquiries and problems, as Andreas Schweiger puts it with a wink:

"It was truly remarkable how swiftly we received responses – sometimes almost too quickly to even process internally."

Customer: pK Chemicals AS

Transparency, gained by the VPS, improves interdepartmental planning and coordination of processes and helps to deliver on time.

Customer: Winter + Freis

The VPS has led to more efficient planning, smoother processes and happier employees at the German manufacturer of transportation equipment and containers.

Customer: Nahrin AG

Summary: A small individual enhancement of the VPS has a great impact on the Swiss food supplements manufacturer's machine utilization.